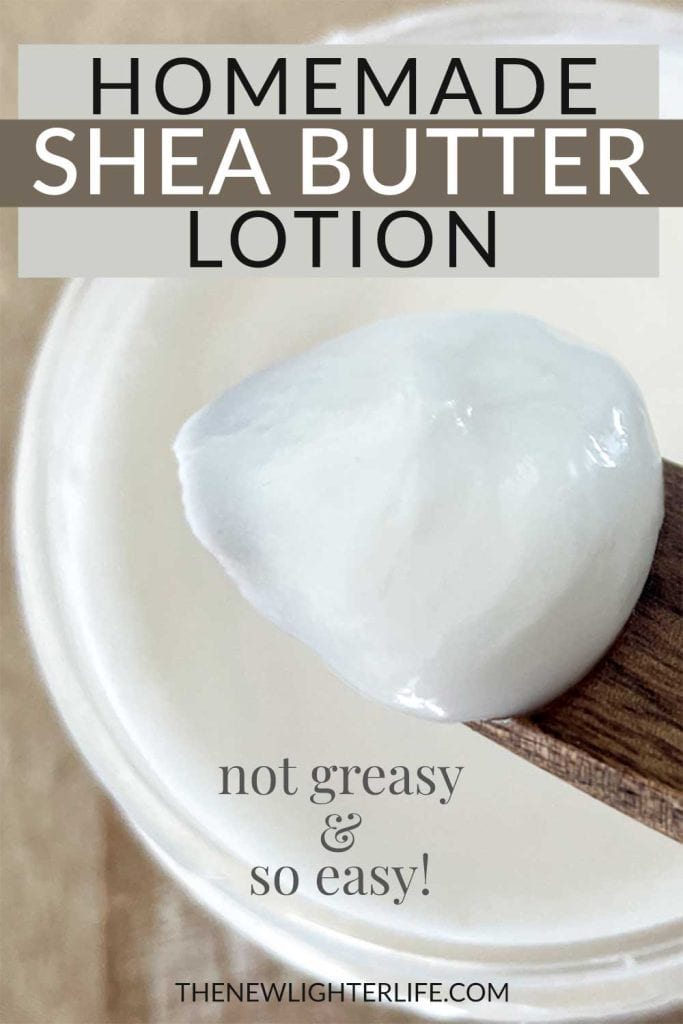

Create Silky Smooth Skin with My Favorite Homemade Shea Butter Lotion Recipe

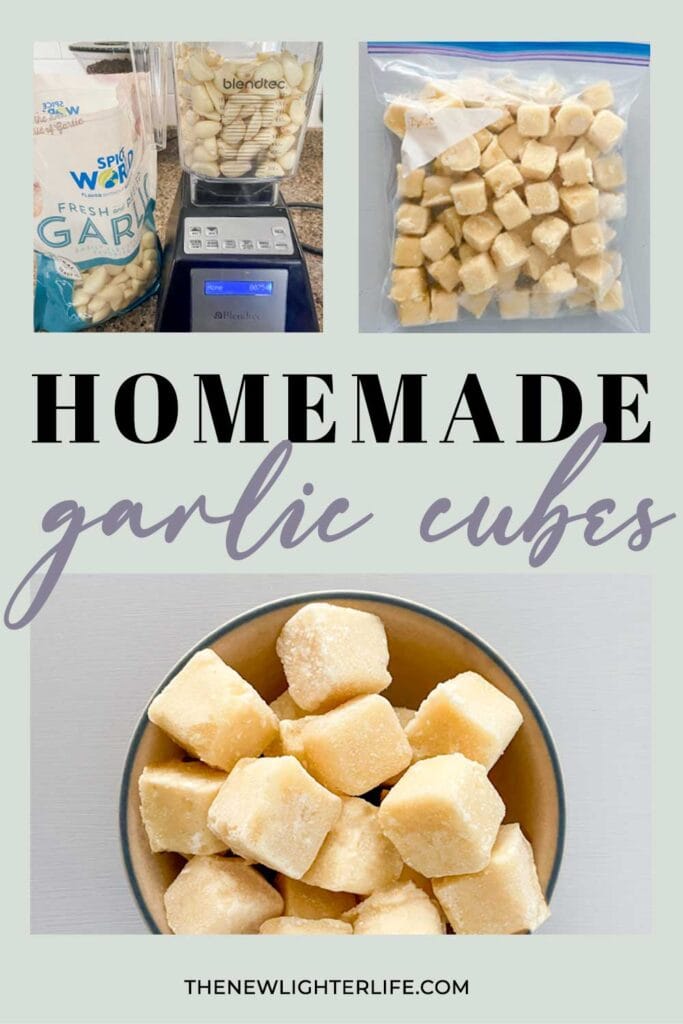

Simplify Your Cooking with Homemade Garlic Cubes: A Must-Have Kitchen Tip

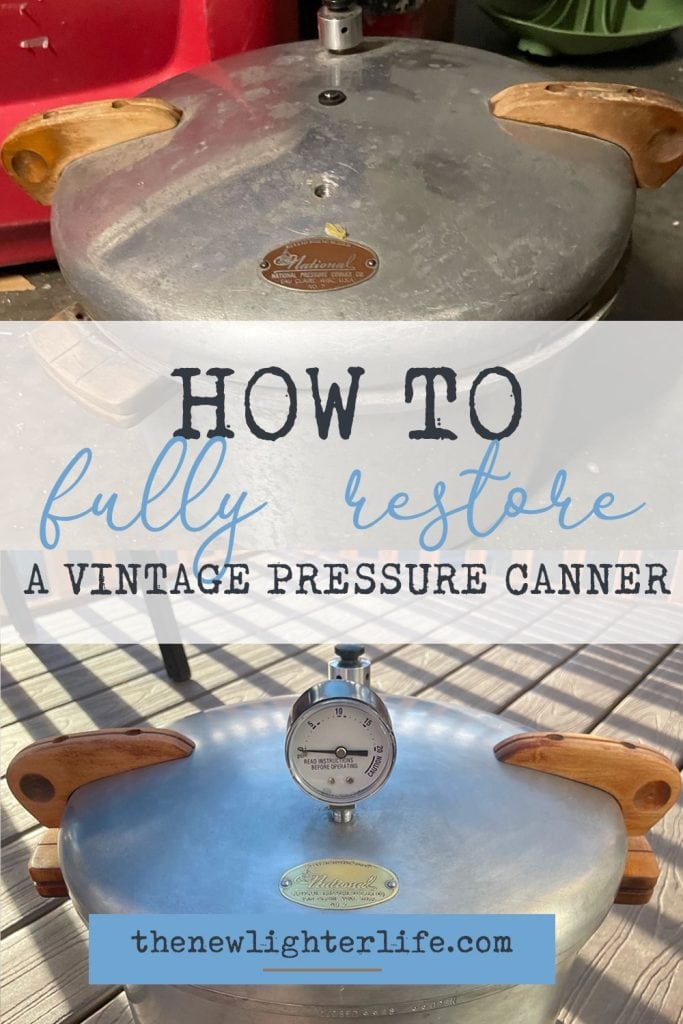

How to Fully Restore a Vintage Pressure Canner

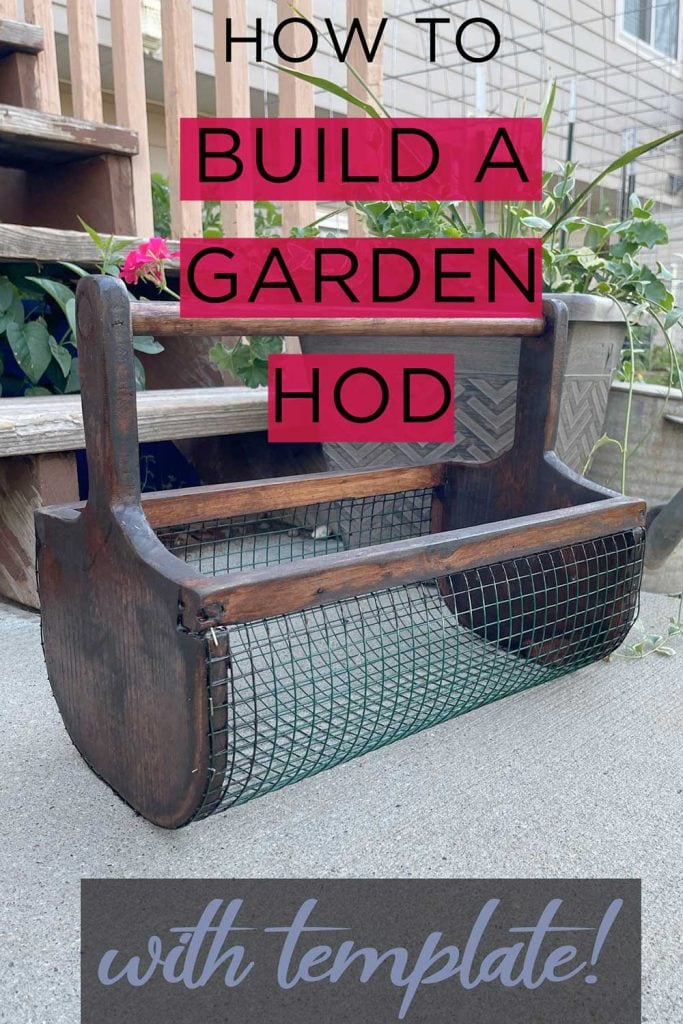

Comprehensive Guide to Make Your Own Garden Hod

8 Unique Window Treatment Ideas

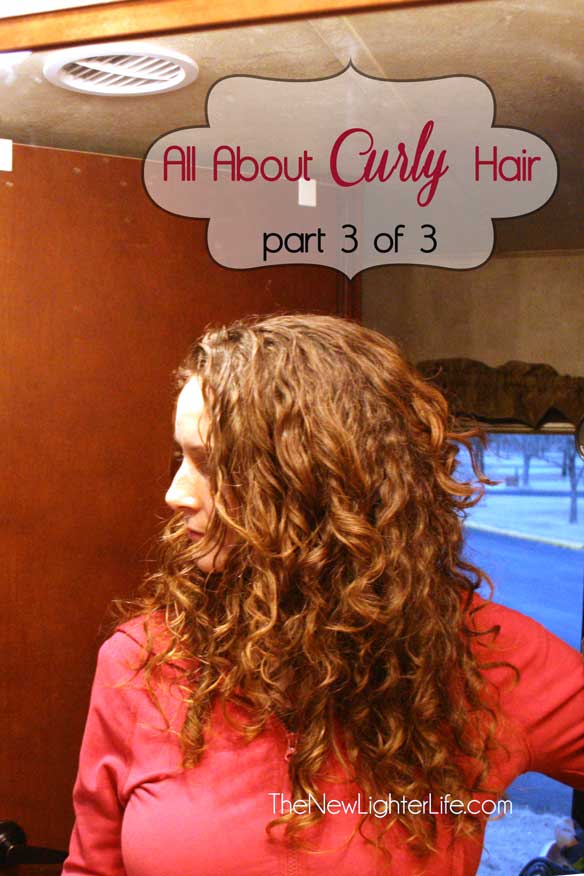

Haircuts for Naturally Curly Hair

Curly Hair Styling Tips

How to Care for Curly Hair – No Poo

A Better Way to Label ~ Chalkboard Spray Paint